Traditional gravity sewer systems use a network of downward sloping, large diameter pipes which allow the forces of gravity to push fluid through the system to a sewer main. This requires extensive digging of trenches which is both costly and has a negative environmental impact, particularly in areas with high ground water and hilly, rocky, or flat terrain. Lift stations required to transport fluid through the sewer main to a collection or treatment plant are costly to build and maintain.

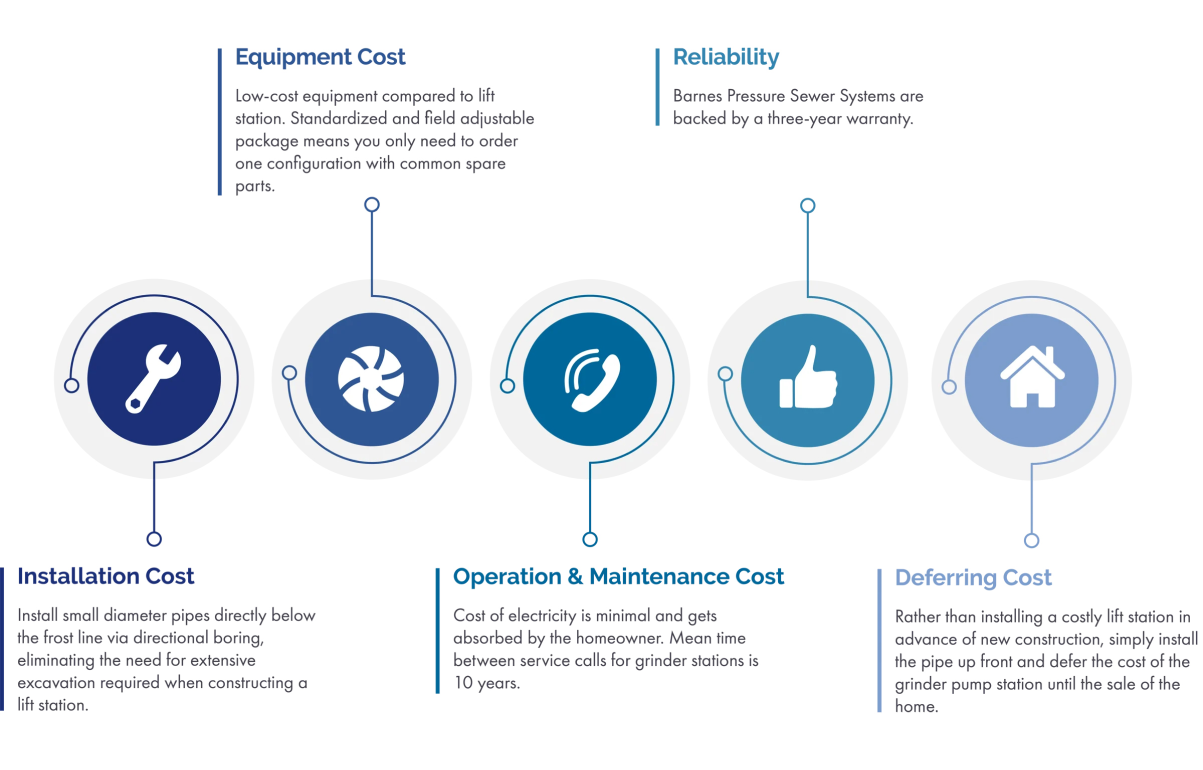

When looking to overcome these challenges, pressure sewer systems provide an attractive and cost-effective alternative. Pressure sewer systems utilize a network of grinder pumps to reduce wastewater particulates into a slurry that can be transported under pressure through small diameter pipes directly to a collection and treatment system. Pressure sewer systems can reduce installation costs, increase system flexibility and reduce the overall environmental impact of the system, all of which benefits contractors and end-users. They can be used as a complete turnkey solution or can be easily integrated into an existing collection system with other technologies.

Lift stations are expensive. They are expensive to construct. The equipment in a lift station is expensive. They require costly maintenance and service. Pressure sewer systems will allow you to eliminate or reduce lift stations in your development, saving you time and money.

Modern grinder pump technology offers improved hydraulics, improved solids handling and cutting capabilities and has been designed for more efficient servicing and maintenance.

Pressure sewer provides an environmentally conscious solution when expanding wastewater infrastructure – providing greater accessibility in hard to service locations and facilitating future growth and development.