Municipal Pump Portfolio

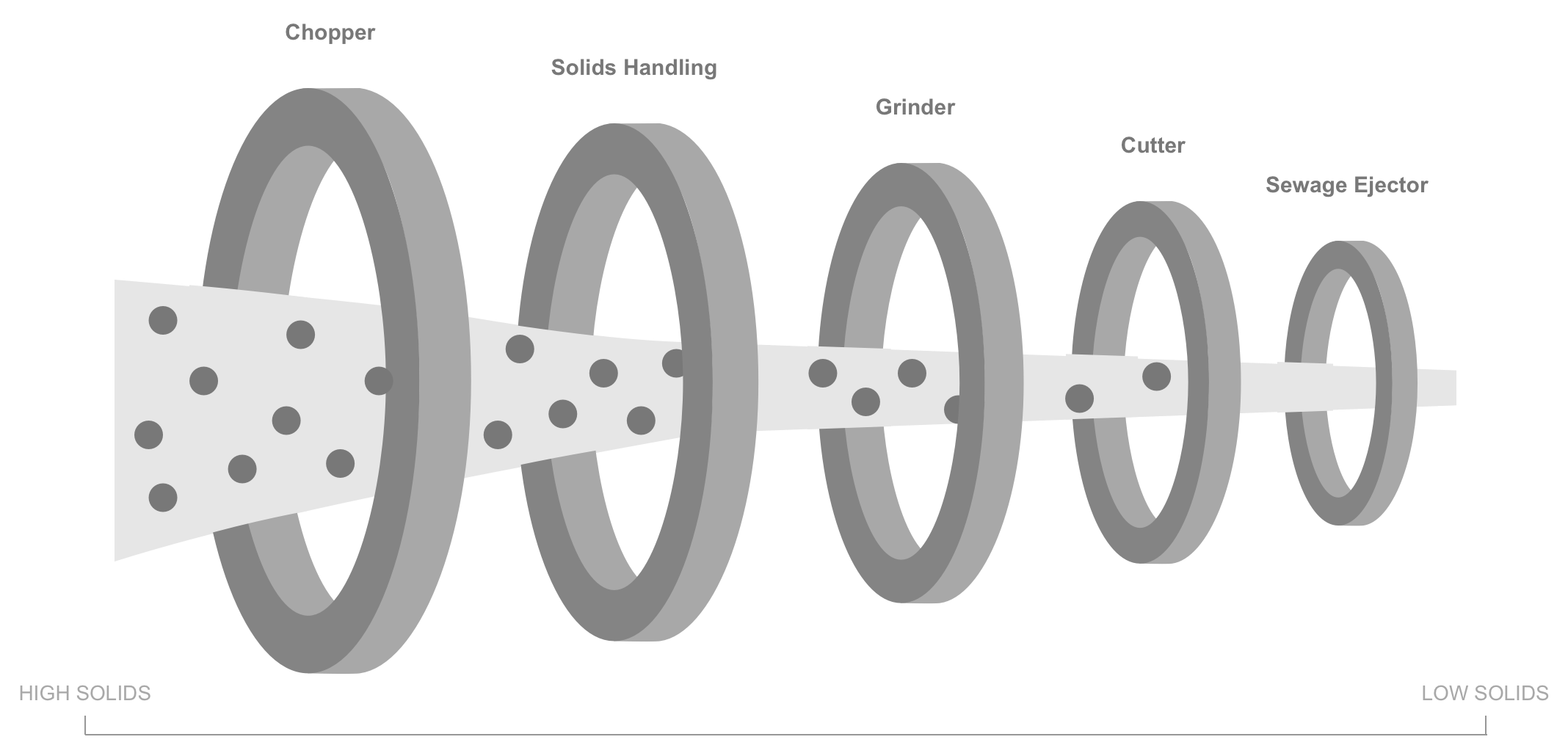

One of the main issues plaguing customers has been and will continue to be the changing waste stream, and the need to handle increasing solids. Picking the right pump for your municipal needs can be difficult. The solids content in your application will have an effect on this decision. Click on each section in the image below to see what products CP&S offers for your solids handling needs for municipal applications.

Chopper Pumps

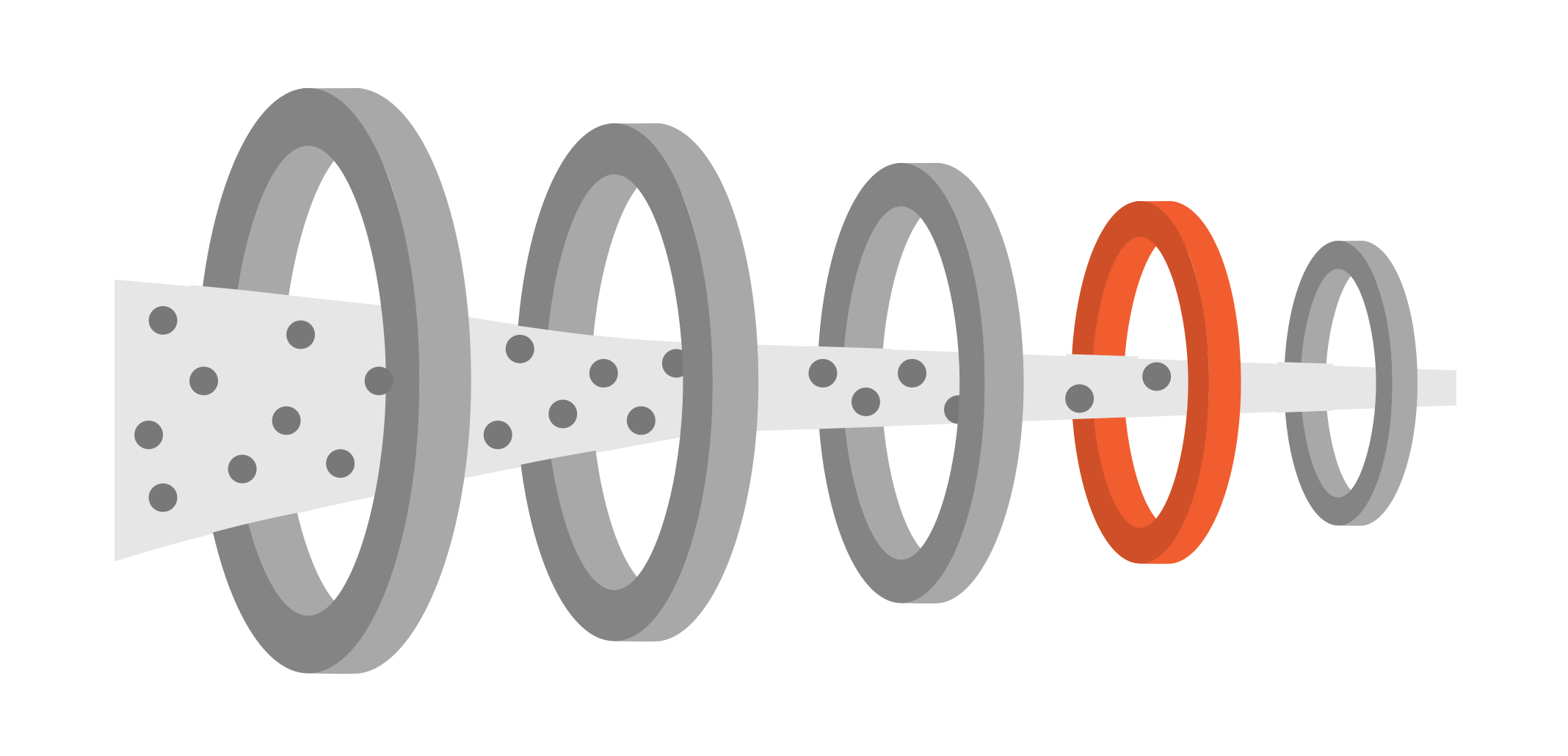

Our chopper platform features oil-filled or air-filled motor housings.

In the oil-filled offering, the oil acts as both a lubricant and coolant, circulating oil through the stator and housing as a heat conductor.

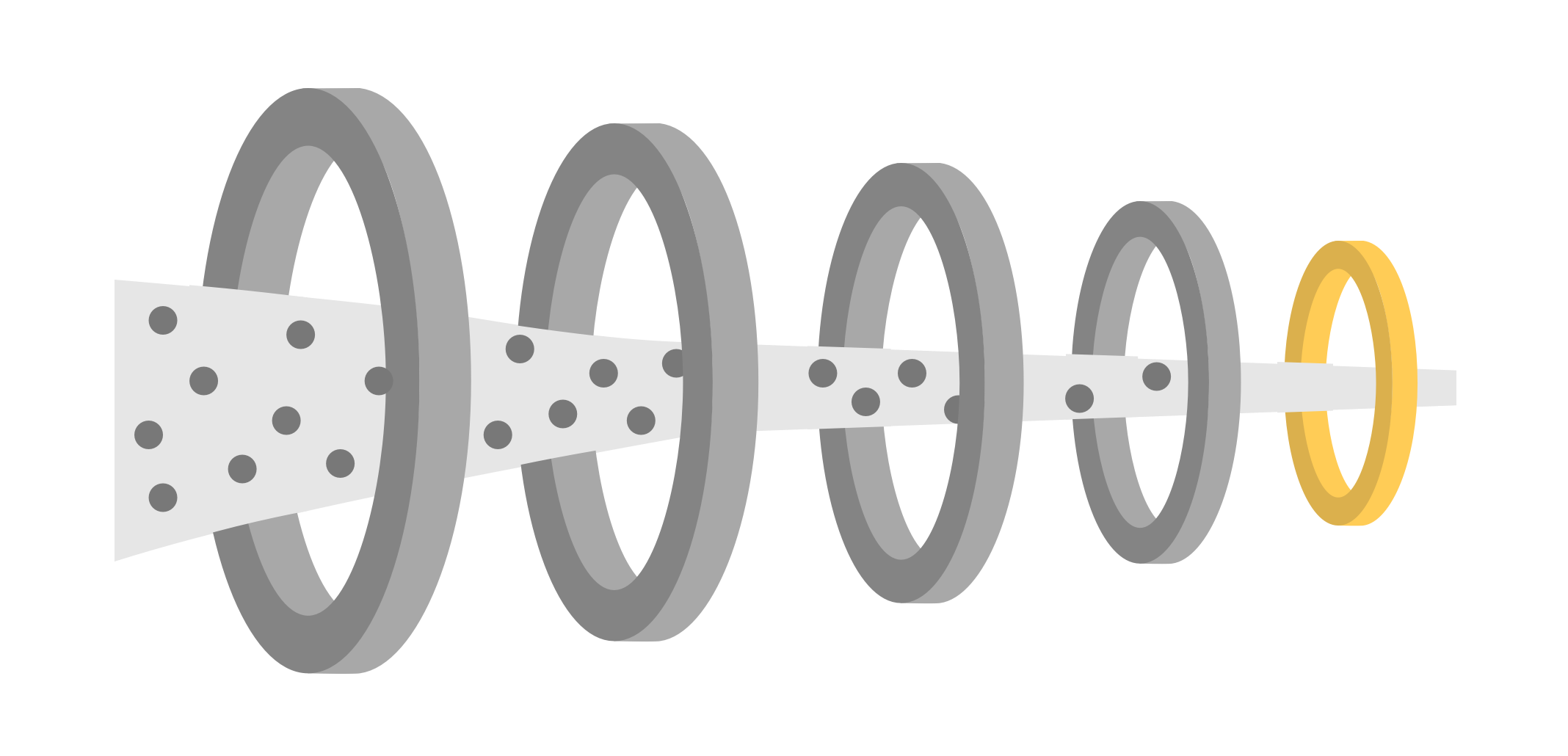

In the air-filled offering, envie3, the pump utilizes a glycol cooling system. This patent-pending cooling system gives envie3 the capability to operate in dry-pit applications and allows lift stations to be shallower. This feature as well as the high efficiency IE3 rating will save time, money, and resources.

There are benefits to both offerings that can be adapted for any need or application. The main difference between the oil filled chopper and air-filled chopper is how the motor is cooled. The slicing mechanism and wet end of the two models are identical to provide the long-lasting reliability of all Barnes products. Whether an oil filled chopper or an air-filled chopper better fits your application, you will experience cost and time savings.

Learn more about the exciting features of each motor type on our product pages.

Product Features

Open center cutter plate design with field replaceable blades provides superior chopping capabilities

Reduce solid size and pass through even the toughest materials

Made in the USA with best-in-class manufacturing lead times

Easy to service plug & play cord and commercially available mechanical seals and bearing components

Rugged and modern design that can withstand the harsh wastewater environment

Suitable for shallow wells, high water tables, and rocky terrain

Watch Us Chop!

Solids Handling Pumps

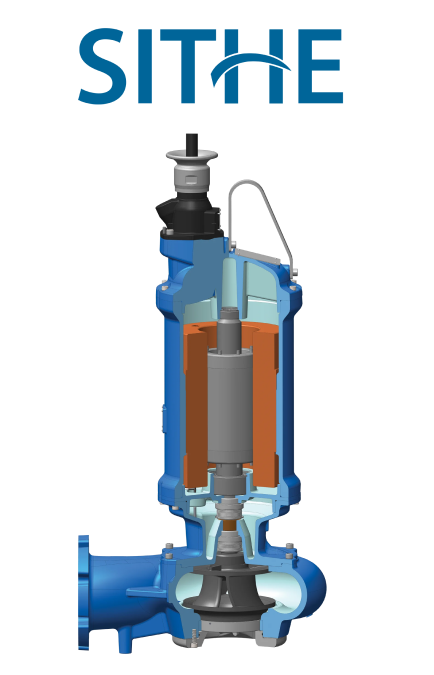

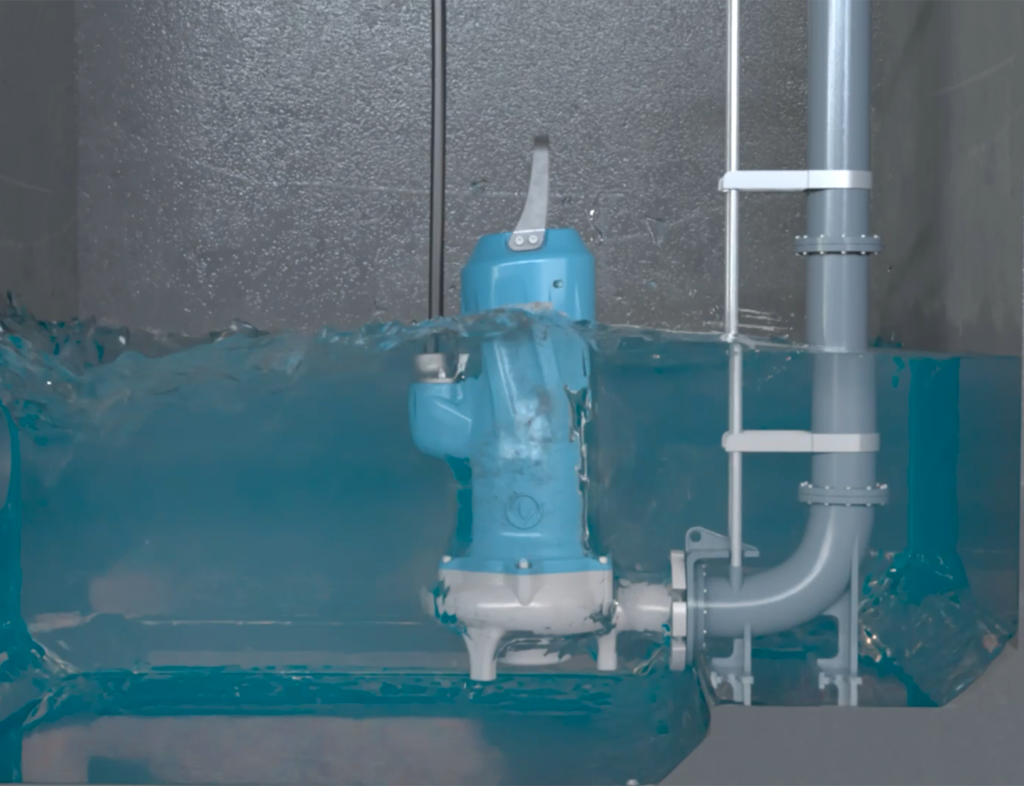

Barnes Solids Handling pumps deliver superior clog resistance and efficiency. Our lineup includes submersible and dry-run submersible motor options to handle tough municipal wastewater applications.

Now introducing SyFlo, a high-efficiency submersible solution with IE3-rated motors, new scroll and vortex impellers, and a compact, easy-to-retrofit design—offering a cost-effective, reliable solution.

For the highest level of performance and versatility, the Barnes envie³ SH is our premium dry-run submersible option. Its closed-loop glycol cooling system allows operation in both wet and dry environments, providing higher efficiency, storm flooding protection, and a 30%+ space-saving close-coupled design—ideal for demanding applications where reliability and versatility are critical.

Explore Our Motor Options:

- Submersible Motors (SyFlo & Oil-Filled SH Models): Reliable, high-efficiency performance for fully submerged applications (SyFlo product page button)

- Dry-Run Submersible Motors (envie³): Designed for maximum efficiency and versatility, operates in dry-pit or wet-well conditions (Button to envie SH product page)

Designed for maximum efficiency and versatility, operates in dry-pit or wet-well conditions

Product Features

Superior Solids Handling: Enhanced clog resistance and improved efficiency ensure peak performance and long service life.

SyFlo Optimized Hydraulic Efficiency: Delivers the same performance you need at an equal or lower horsepower than alternatives.

Manufactured in the USA and utilizes lean manufacturing to eliminate downtime.

Combines power, temperature sensing and moisture sensor conductors into a single cable for simplified installations and quick repairs

SH envie3 pumps have a patented closed loop glycol cooling system that keeps motors stress-free.

Large stainless steel lifting bail making installation and service easier

Grinder Pumps

Don’t have a ton of flow or need a lot of head at your waste station? A grinder pump might be the right solution for your needs. Barnes by Crane Pumps & Systems offers two grinder product families.

The RAZOR is a 2 HP grinder pump for residential and light commercial solids handling applications. With the Razor’s thoughtfully designed innovative axial cutting technology, it is engineered to efficiently reduce solids like flushable wipes, diapers, and other non-biodegradable items.

Need a little more power? The Blade is a 3 – 15 HP grinder pumps for wastewater applications requiring high capacity, high head and high flow.

Patented Axial Cutter

Provides superior non-clogging versus radial designs

Tank Mixing

Fat, oil, and grease build up is prevented by constant water movement

Easy Serviceability

Thoughtful, lightweight design requires only one tool for service

Explosion Proof Design

Product portfolio expanded to include explosion proof models suitable for hazardous locations

Plug and Play Cord

Simplifies pump installation and serviceability with quick disconnect capabilities

Proven Technology

Proven history of solids-handling capabilities

Configuration Options

Available in vertical or horizontal discharge for simple installation and replacement

Explosion Proof Design

Optional explosion proof design gives an added peace of mind for pump operation and safety in hazardous locations

Cutter Pumps

Designed to solve clogging in municipal application with light solids content, the Barnes SEC Cutter Pump is a 2–5HP offering that is packaged to retrofit into multiple installation types. Each pump is equipped with a JIS 80 discharge flange. Accessories are packaged with each pump to accommodate installations.

Superior Cutting

Steel cutting plate and impeller blade provide superior cutting.

Rugged Pump Design

Constructed with ASTM A-48 Class 30 Cast Iron

Adaptability

Removable stand and discharge accessories to fit perfectly in free-standing installations or on a variety of guide rail systems

Air Filled Motor

Air filled motor protected with integral moisture and temperature sensors

Package Features

3 Inch NPT Vertical Elbow: For use with the 2HP SEC Cutter.

4 Inch ANSI Class 125 Flange (with 4 Inch NPT threads) Vertical Elbow: For use with the 3HP and 5HP SEC Cutter.

JIS 80 to 4 Inch ANSI Horizontal Flange Adapter: For use with the 3HP and 5HP SEC Cutter.

Sewage Ejector Pumps

Sewage ejector pumps play a crucial role in managing wastewater in buildings below the main sewer line. Typically installed in basements or lower levels, these pumps facilitate the movement of sewage and greywater to higher elevations, ensuring efficient disposal into the main sewer system.

Barnes sewage ejector pumps are known for their quality and reliability. Manufactured by Crane Pumps & Systems, the Barnes SE and SEV sewage ejector pumps feature robust construction. These pumps are designed to handle demanding sewage and wastewater conditions, incorporating durable materials to withstand corrosive elements.

Barnes sewage ejector pumps are available in various models, catering to different capacity and head requirements. This technology is essential for properties where gravity alone isn’t sufficient for sewage drainage, offering a reliable solution for effective and hygienic waste removal.

SE/SEV Pump Features

Heavy duty upper and lower ball bearings are oil lubricated for superior cooling and maximum life

The pump utilizes a combination of cast iron and stainless steel components to stand up to the toughest sewage ejector applications

Capable of handling between 2-3 inch spherical solids which help prevent clogging