When it comes to submersible pumps and submersible pump motors, performance isn’t just about horsepower. It’s about reliability, efficiency, and confidence in your system. Whether you’re managing a wastewater facility, designing an industrial process, or upgrading municipal infrastructure, the motor you choose can make all the difference.

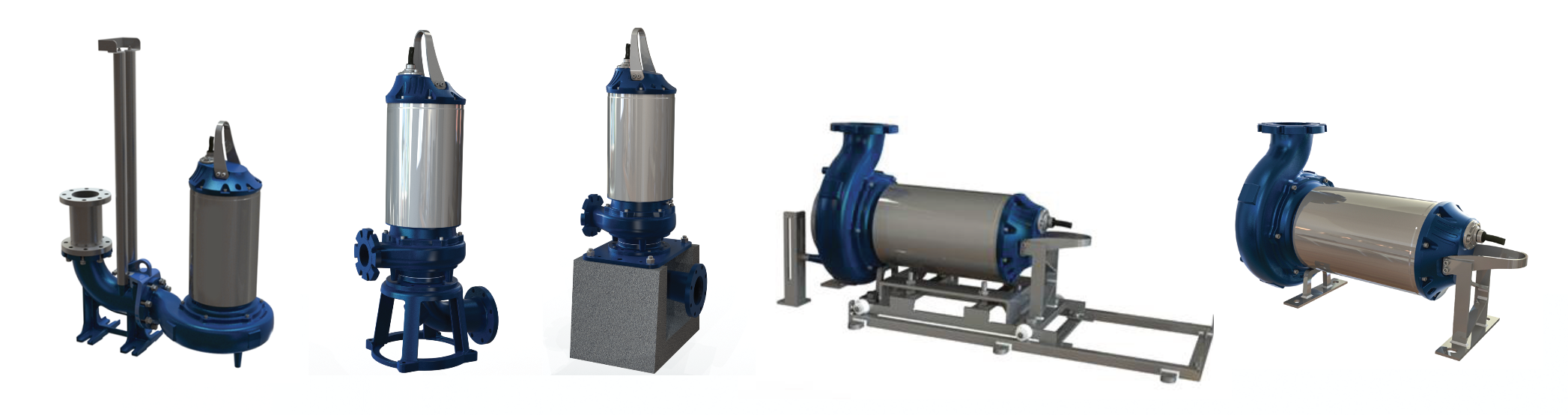

In this post, we’ll break down the two main types of submersible pump motors, oil-filled and air-filled with cooling jackets, helping you decide which one fits your needs best.

Why the Right Submersible Motor Matters

Submersible pumps are designed to operate underwater, often in demanding environments. At the heart of every pump is a motor: a sealed, rugged workhorse that powers the system and keeps everything running smoothly.

Choosing the right motor isn’t just a technical decision. It’s a strategic one. The wrong motor can lead to overheating, seal failures, and costly downtime. The right motor? It delivers peace of mind, long-term savings, and optimal performance.

Inside a Submersible Motor: What You Need to Know

Every submersible motor includes:

- Rotor & Stator: The core components that generate motion and power.

- Bearings: High-capacity, oil or grease-lubricated bearings that keep the rotor spinning smoothly.

- Mechanical Seals: Dual seals that protect the motor from fluid ingress and prevent coolant leaks.

- Moisture Sensors: Early-warning systems that detect seal failures before they become disasters.

- Waterproof Cables: Sealed connections that deliver power and sensor data reliably.

These components work together to ensure your pump runs efficiently in even the toughest conditions.

Oil-Filled Submersible Motors: Built for Submerged Strength

Oil-filled motors are filled with dielectric oil that lubricates bearings and helps dissipate heat. They’re designed to operate fully or partially submerged, making them ideal for continuous-duty applications.

Benefits:

- Continuous lubrication for longer bearing life

- Effective heat dissipation across the motor housing

- Higher service factor for increased power output

Considerations:

- Lower energy efficiency due to fluid drag

- Must remain submerged to avoid overheating

- Not suitable for dry pit installations

If your application involves constant submersion and steady operation, oil-filled motors offer a dependable solution.

Air-Filled Motors with Cooling Jackets: Flexible, Efficient, and Smart

Air-filled motors use convection and cooling jackets to manage heat. These motors are perfect for dry pit submersible pumps, low-water-level environments, or installations where flexibility is key.

Cooling Jacket Options:

- Closed-loop glycol-water system: Circulates coolant using a motor-driven propeller.

- External water jacket: Uses clean water from an external source.

- Pumped fluid jacket: Circulates the pumped fluid (less common due to clogging risk).

Benefits:

- High efficiency (often IE3-rated or better)

- Can operate unsubmerged

- Ideal for dry pit or fluctuating water levels

If you’re looking for energy savings, installation flexibility, and modern performance, air-filled motors are a smart investment.

Making the Right Choice for Your Application

When selecting a motor for your submersible pump, ask yourself:

- Will the pump be fully submerged at all times?

- Is energy efficiency a top priority?

- Do you need flexibility for dry pit or low-water-level operation?

- Are you looking to reduce long-term maintenance costs?

Your answers will guide you toward the motor that delivers the best value, performance, and longevity.

Check out our catalogs for more detailed product information organized by motor type.

Final Thoughts: Confidence Starts with the Right Motor

At the end of the day, your submersible pump is only as reliable as the motor driving it. Whether you choose an oil-filled motor for rugged, submerged applications or an air-filled motor for flexible, high-efficiency performance, the right pairing ensures your system runs smoothly and your team sleeps better at night.

Need help choosing the best motor for your submersible pump? Our experts are here to guide you every step of the way.

Contact us today to find the perfect motor for your application.

This information was first published with Pumps & Systems Magazine.